Failure Analysis

Course Objectives: :-

- Failure analysis is the logical, systematic examination of an item, its construction, application, and documentation to identify the failure mode and to determine the failure mechanism and its basic cause.

- This program aims to increase the capabilities of engineers as well as technicians to understand the material behavior and select the proper material for each specific application to prevent spare parts damage in service. Some highlights will be focus on how the spare parts can be damaged and what the different modes of fracture are. This technical course covers also the failure that could be happened in all industrial sectors (engineering, petroleum, chemical, medical, etc.). In order to clarify the theoretical theories of failure analysis, some case studies in different sectors will be involved in this course. In addition, the engineers will learn how to reporting a failure analysis case study to prevent its occurrence in future.

Course Outlines:

- Introduction to materials selection (Ferrous alloys & Non-ferrous alloys)

- Introduction to fracture mechanics

- Fracture mechanics concepts

- Fracture toughness according to ASTM standard

- Plain strain fracture toughness test (K1C)

- Fatigue crack growth rate test (FCGR)

- Crack opening displacement test (CTOD)

- Types of fracture surface

- Introduction to wear failures

- Examples of wear failure and how to avoid it in service.

- Introduction to failure analysis

- Fracture modes macro-fractographic features

- Corrosion failure analysis

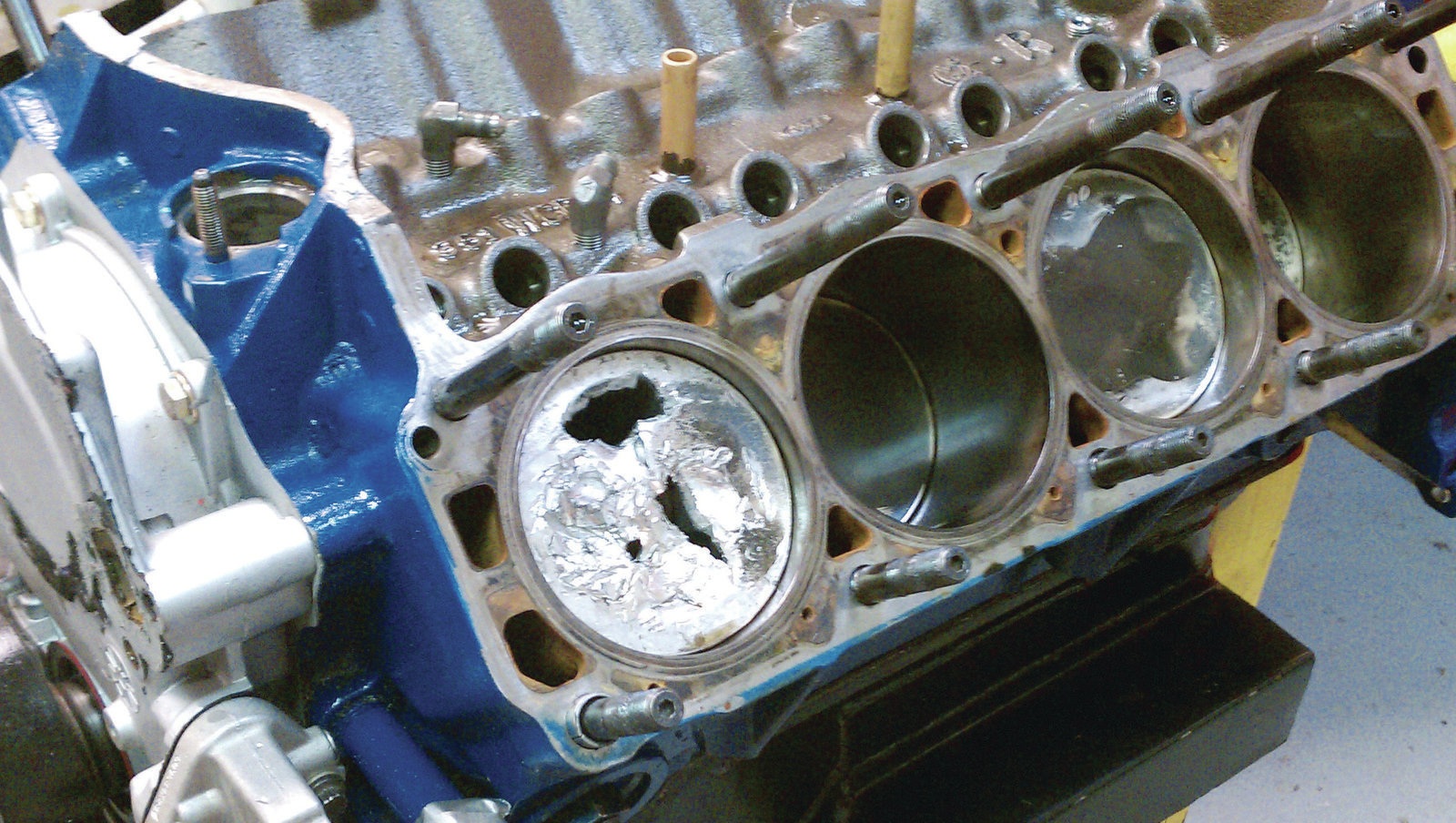

- Case studies on failure analysis

- How to avoid failure in service

- How to report the Failure case

Training Plan

| Download our Training Plan |

|